Category

Mini Laser Welder 1000W Hand Held Portable Fiber Laser Welding Cutting Cleaning Machine 4 in 1 for Stainless Steel

Overview Package Size 700.00cm * 1300.00cm * 1500.00cm Package Gross Weight 240.000kg Product Description One laser mach

Overview

Features

1. Multifunction fiber laser machine, can weld, clean and cut metallic materials;2. Handheld type with longer holder cable length;3. Welding function conversion cleaning function, just replace the focusing lens and laser head;4. Small machine body, can move easily. It is very convenient.

Detailed Photos

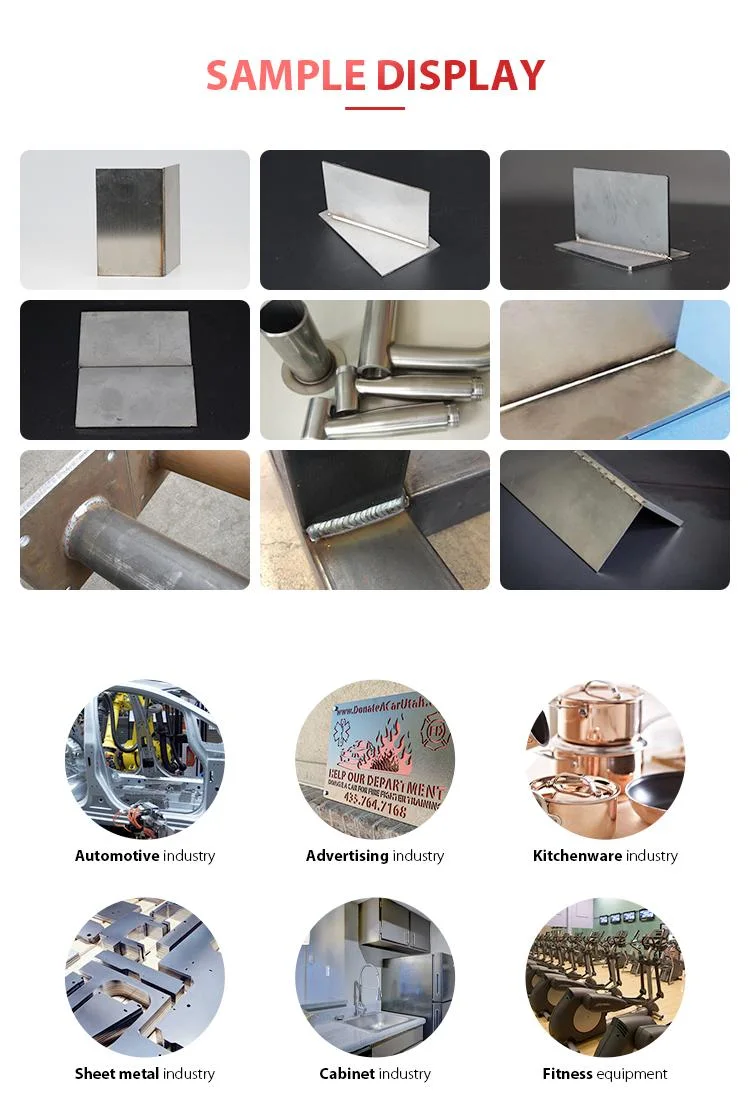

Laser head--The portable welding joint is light,flexible and easy to operate.it can be used for continuous welding of various angles and positions.Control Panel--The operation is simple and clear,and the system supportsmultiple languages. Laser Source--Compared with similar products,the light laser has a higher photoelectric performance conversion ability ,a more stable beam,and a stronger anti-reflection ability. Cutting Sample

Certifications

FAQ1. Do you have the CE document and other documents for customs clearance?

A: Yes, we have the Original. At first, we will show you and after shipment, we will give you CE/Packing list/CommercialInvoice/Sales contract for customs clearance.

2. Payment terms?

A: Alibaba trade assurance/TT/West Union/Paypal/LC/Cash and so on.3. What's the max. cutting thickness?

A: Cutting thickness is related to laser power.Note: only 1KW or above fiber laser could cut Aluminum, Copper, Brass, and other high-reflection sheet metal.4. Which kind of materials can be processed on this machine?

A: Wood, MDF, stone, acrylic, glass, plastic, foam, aluminum, copper, and almost all kinds of non-steel materials.5. How long is the delivery time?

A: For standard machines, it will be 7-10 days; For non-standard machines and customized machines according to the client's specific requirements, it will be 15 to 30 days.

Basic Info.

| Model NO. | CCW-Series |

| Technical Class | Continuous Wave Laser |

| Control | Automatic |

| Power Density | Deep Fusion Welding |

| Laser Classification | Customized |

| Type | Fiber Laser |

| Weld Thickness | 2-2.5mm/2-2.5mm/3-4mm/5-6mm |

| Power Consumption | 7kw / 8.2kw / 9.8kw / 13.9kw |

| out Power Stability | <2% |

| Machine Size | 700*1500*1300mm / 1500*750*850mm |

| Machine Weight | 240kgs / 160kgs |

| Model | Regular / Mini |

| Cleaning Width | 10-200mm |

| Pulse Width | 0.05-0.6 |

| Laser Wavelength | 1080±5nm |

| Laser Type | Continuous |

| Laser Source | Fiber Laser |

| Machine Power | 1000W / 1500W / 2000W / 3000W |

| Transport Package | 3 Layers |

| Specification | more than 4500kg |

| Trademark | DXTECH |

| Origin | Jinan, Shandong Prvovince, China |

| HS Code | 8461500090 |

| Production Capacity | 100 Sets/Month |

Packaging & Delivery

Package Size 700.00cm * 1300.00cm * 1500.00cm Package Gross Weight 240.000kgProduct Description

Product DescriptionOne laser machine can do laser welding, laser cleaning and handheld metal cutting together. No need to buy several laser machines for these different laser process jobs. Our laser system is very suitable for stainless steel & aluminum alloy welding, also can do welding on carbon steel, titanium alloy and etc. Also it can be used for rusty removal and handheld metal cutting.

Features

1. Multifunction fiber laser machine, can weld, clean and cut metallic materials;2. Handheld type with longer holder cable length;3. Welding function conversion cleaning function, just replace the focusing lens and laser head;4. Small machine body, can move easily. It is very convenient.

| Machine power | 1000w / 1500w / 2000w / 3000w |

| laser type | continuous |

| Laser source | Fiber laser |

| Cleaning width | 10-200mm |

| Laser wavelength | 1080±5nm |

| Pulse Width | 0.05-0.6 |

| Out power Stability | <2% |

| Weld thickness | 2-2.5mm/2-2.5mm/3-4mm/5-6mm |

| Power Consumption | 7KW / 8.2KW / 9.8KW / 13.9KW |

| Fiber optical length | 10m |

| Model | Regular / mini |

| Machine size | 700*1500*1300mm / 1500*750*850mm |

| machine weight | 240KGS / 160KGS |

Laser head--The portable welding joint is light,flexible and easy to operate.it can be used for continuous welding of various angles and positions.Control Panel--The operation is simple and clear,and the system supportsmultiple languages. Laser Source--Compared with similar products,the light laser has a higher photoelectric performance conversion ability ,a more stable beam,and a stronger anti-reflection ability. Cutting Sample

Certifications

FAQ1. Do you have the CE document and other documents for customs clearance?

A: Yes, we have the Original. At first, we will show you and after shipment, we will give you CE/Packing list/CommercialInvoice/Sales contract for customs clearance.

2. Payment terms?

A: Alibaba trade assurance/TT/West Union/Paypal/LC/Cash and so on.3. What's the max. cutting thickness?

A: Cutting thickness is related to laser power.Note: only 1KW or above fiber laser could cut Aluminum, Copper, Brass, and other high-reflection sheet metal.4. Which kind of materials can be processed on this machine?

A: Wood, MDF, stone, acrylic, glass, plastic, foam, aluminum, copper, and almost all kinds of non-steel materials.5. How long is the delivery time?

A: For standard machines, it will be 7-10 days; For non-standard machines and customized machines according to the client's specific requirements, it will be 15 to 30 days.